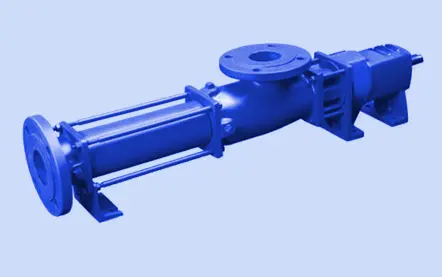

Progressive Cavity Screw Pump Manufacturer

Airvac Progressive Cavity screw Pumps are designed to pump ‘tough – to – handle’ fluids with ease in varied industries. These pumps are usually used in Water Treatment Plant (STP/ETP), Chemical, Pharmaceutical, Ceramic, Food, Paper industries. Screw pump manufacturers have the capacity of pumping or transferring high and low consistency products, with or without solids or long fibers, in suspension. Likewise, these Progressive Pumps are checked on various quality parameters to ensure their abrasion and corrosion resistance nature. The construction of these screw pumps is based on the modular concept and comprises of next generation pumping elements i.e. Rotor, Stator, Solid Shaft and Double Sealed Cardan Universal Joints for improved performance and longer service life. With their commitment to quality and consumer satisfaction, you can be guaranteed that you're getting the best products for your requirements.

Mastering the art of conquering the most formidable fluids across diverse industries, these pumps epitomize engineering excellence. Embracing a modular design concept, they boast cutting-edge pumping elements, including the majestic Rotor and Stator, fortified Solid Shaft, and the formidable Double Sealed Cardan Universal Joints, synergistically enhancing their performance and bestowing upon them a life that defies limits. Available in both the bare shaft and close coupled configurations, these pumps offer a harmonious blend of power and flexibility.

Embracing a range of sizes, from single stage to multistage, they stand poised to conquer every challenge. With options galore, encompassing varied material grades and shaft sealing, Airvac Progressive Cavity Pumps grant you the freedom to customize and redefine the boundaries of possibility.

Single Stage Pump

Capacity: up to 200 m3/hr

Pressure: up to 6 bar

These Heavy Duty cost effective pumps use the extended Rotor, Stator Geometry and results in lower rubbing velocities which are ideal for various applications.

Multi Stage Pump

Capacity: up to 150 m3/hr

Pressure: up to 12 bar

These heavy duty pumps are designed for continuous or intermittent duty and are suitable to perform efficiently even for the most difficult fluid handling applications in various industries.

- Easy to maintain.

- Pumps almost all type of slurry fluids.

- These pumps provide constant and non-pulsating fluid flow.

- The pump can produce greater volumetric efficiency.

- High reliability and robustness.

- Self-priming capability

- High resistance to water vapor and particles/dust.

- No contamination of the pumped medium

- High efficiency due to internal compression.

- Relatively low operating costs and maintenance requirements.

- Inverter operation – easily optimized for process requirements – resulting in high energy efficiency

Applications

Airvac Progressive Cavity Pumps are versatile and can be used in various industries. Some of the industries where these pumps find applications include: