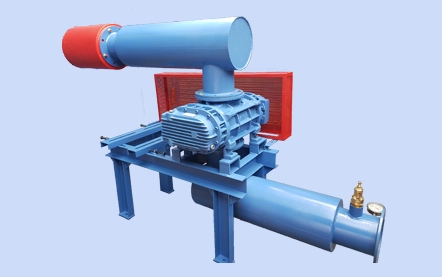

Tri Air Lobe Blower Manufacturer

Airvac's cutting-edge Tri-Lobe Blower, with its unique 120-degree tip arrangement, revolutionizes blower technology. It ensures a stiffer rotor, enhanced volumetric efficiency, lower operating temperatures, and reduced vibrations and noise, making it an ideal and innovative choice for various applications. Airvac is a leading tri lobe blower manufacturer in India. It is sagely manufactured under the direction of experienced experts utilizing best grade materials secured from reputed vendors of the market.. This blower is quicker than an ordinary twin lobe blower with an extra siphoning limit of another blower into the system. These blowers are supplied with built-in safety & monitoring equipment, for example, safety relief valve and pressure gauge.

Embark on a transformative journey with Airvac's groundbreaking Tri-Lobe Blower, a result of cutting-edge technology and design adaptation. With a capacity range of 100 m3/hr to 15,000 m3/hr at a working pressure of 1kg/cm2, it guarantees 100% oil-free air delivery. The Tri-Lobe configuration, featuring a 120-degree tip arrangement instead of the conventional 180 degrees, ensures a stiffer rotor that resists deflection under any load. This unique design elevates volumetric efficiency, reduces operating temperatures, and minimizes vibrations and noise, making it the ideal solution for diverse applications. Unleash the potential of the Tri-Lobe Blower, setting new benchmarks in performance, efficiency, and reliability.

- Airvac blowers are designed with leak proof sealing arrangement for 100% oil free applications.

- Factory engineered, factory guaranteed, superior product.

- Precision case hardened and ground helical gears for smooth and quieter operation.

- Anti-friction bearings.

- All rotating parts are dynamically balanced for smooth running and before putting on bearings.

- Rugged construction for heavy-duty application

- Rotary oil sealings.

- Rigid one piece CI casing and side plates.

- Split casing design facilitates easy maintenance and repair

- High efficiency with lower power consumption

- Horizontal and vertical configurations available.

- Easy rotor timing setting.

- No vanes, valves or rings to wear.

- Large inlet and outlet connections for minimum loss.

- Improved volumetric efficiency and reduced operating temperatures.

- Alloy steel toughened shafts ground to close tolerances.

- Common Motor & Compressor base frame with Motor base plate and belt tightening arrangement.

- Suction Silencer (M.S)

- Discharge Silencer (M.S)

- Suction Air Filter (Dry Bag Type)

- Pressure Gauge

- Pressure Relief Valve (Spring Loaded Type)

- V-Belts and V Belt Guard

- Non-Returnable Valve

- Foundation bolts

- Lubrication Oil

- Set of Drive & Driven Pulleys

- Interconnecting line with flanges

- Operation & Maintenance Manual

- Electric Motor

- SS Expansion Bellows)

Applications

Air Blower can find applications in various industries where reliable and efficient air circulation or ventilation is required. Some industries where Air blowers can be applied include: